Uganda raises purity standards for tin exports

In another blow against exports of raw minerals, Uganda has raised standards for tin, requiring exporters to process the ore to 99.85pc purity.

Signing the instrument setting the new standards, energy and mineral development minister, Dr Ruth Nankabirwa, said the measure was aimed at enhancing value addition to Ugandan minerals before export.

“I am happy today to sign a Statutory Instrument on the Level of Purity of Tin as a Mineral,” Dr Nankabirwa said December 22, explaining that the decision aligns with an earlier order by President Museveni banning exports of unprocessed minerals, including tin.

Under the new statutory instrument, the minimum purity level for tin exports has been raised from the previous range of 67- 70pc, to 99.85pc. The change is expected to transform the tin mining and processing industry in Uganda and enhance value retention.

Dr. Nankabirwa revealed that the instrument paves the way for Wood Cross, a company that has recently established a tin smelting plant in Mbarara, Western Uganda, to start commercial operations. “They have been waiting for this statutory instrument to commence tin processing,” she said.

Commissioning of the plant is expected at some point in January.

The minister also cautioned against tin smuggling, warning that the government would intensify monitoring to protect the industry and ensure the availability of raw materials for the new smelting plant. “We are going to swing into operations to make sure that this company is not denied raw materials,” she said.

Looking ahead, Dr Nankabirwa revealed that similar purity standards would soon be introduced for other minerals like vermiculite and the 3Ts (Tin, Tantalum, and Tungsten). “Vermiculite and the 3Ts are to be dealt with very fast,” she added.

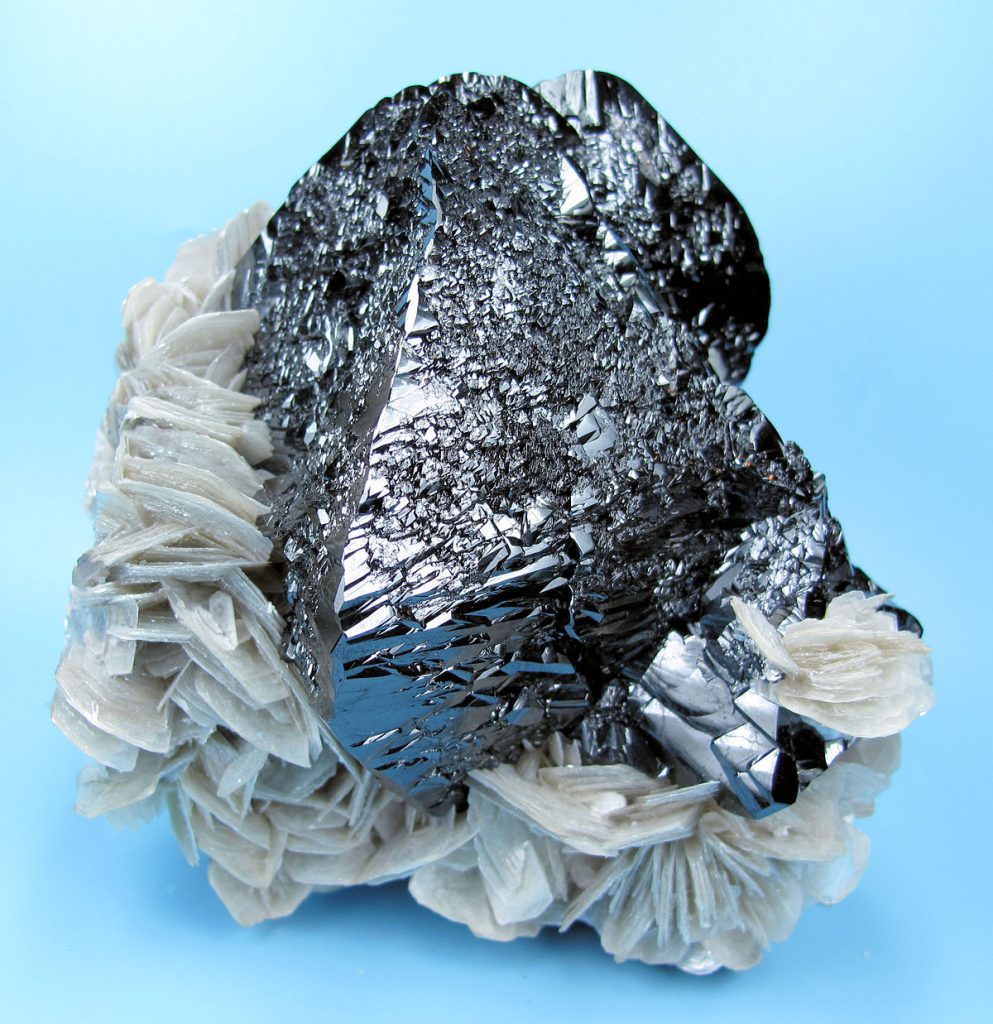

Tin, which is predominantly mined in the western Uganda areas of Isingiro, Ntungamo and Mbarara, is primarily used in solder, an alloy that is essential for joining pipes and electronic circuits. It’s also used in plating, to prevent corrosion, and in various alloys, such as bronze.

The 3T minerals are often grouped together due to their related uses and the challenges associated with their mining and trading.

The new policy is expected to create job opportunities and significantly boost revenue from mineral exports. “We’ll make much more money in this processed tin than the semi-processed tin,” Dr Nankabirwa concluded, underscoring the economic benefits of this new regulation.

Unpacking results-based financing: balancing strengths with weaknesses

Unpacking results-based financing: balancing strengths with weaknesses

Mergers and degradations predicted as Uganda lenders move to comply with higher capital thresholds

Mergers and degradations predicted as Uganda lenders move to comply with higher capital thresholds

Regional tentative policy to govern cross-border labour gets approval

Regional tentative policy to govern cross-border labour gets approval

Uganda on edge of debt distress, needs 35 years to settle domestic arrears

Uganda on edge of debt distress, needs 35 years to settle domestic arrears

CSBAG warns fiscal indiscipline and runaway graft a threat to Uganda’s economic recovery

CSBAG warns fiscal indiscipline and runaway graft a threat to Uganda’s economic recovery

Suspected Ethiopian diplomatic breach leads to AfDB partial staff exit

Suspected Ethiopian diplomatic breach leads to AfDB partial staff exit