Kiira Motors, Makerere University begin tests of home grown medical ventilator

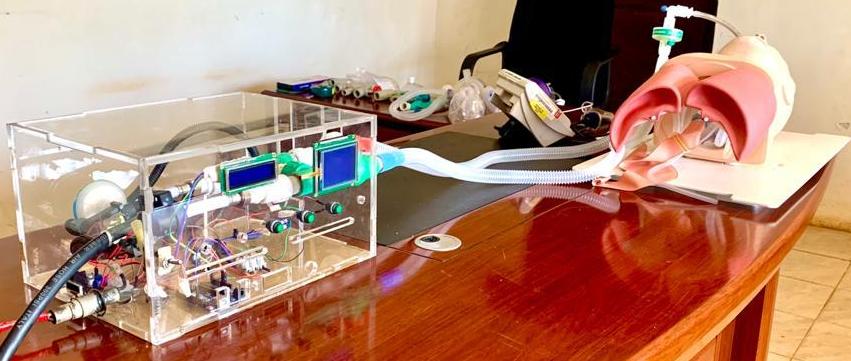

The prototype of the Ventilator that is being developed by a joint team from Kiira Motors Corporation and Makerere University School of Public Health. Initial functionality tests are complete while endurance tests and trials on live animals start later this week. Clinical trials are scheduled in a weeks time.

The prototype of the Ventilator that is being developed by a joint team from Kiira Motors Corporation and Makerere University School of Public Health. Initial functionality tests are complete while endurance tests and trials on live animals start later this week. Clinical trials are scheduled in a weeks time.

Efforts by Ugandan engineers to put a homegrown medical ventilator to market reached a major milestone on April 10, with the commencement of bench-tests on a prototype.

The prototype is the culmination of joint efforts by Uganda’s budding automotive manufacturer Kiira Motors Corporation, and the Makerere School of Public Health, who have been quietly working to develop a low-cost open design ventilator that can be rapidly put on the market to address the spiraling demand for the devices.

Sources familiar with the project told 256BN that the tests are being conducted using artificial lungs under the supervision of two medical doctors from Mulago hospital. But they will soon advance to live animals under the supervision of a Vet. The live animal tests will help establish the functionality of the design in a real life environment. Clinical trials on humans will follow soon after.

Although it has gained a sense of urgency in light of the Novel Coronavirus (COVID-19) pandemic that has rapidly spread across the world, the project is partly informed by Uganda’s own acute lack of ventilators, which are critical to assisting respiration during the treatment and management of severe cases of patients with compromised breathing.

Uganda has so far reported 53 cases of COVID-19, none of which has progressed to the acute stage. But that is way too close to the margin of existing ventilator capacity in the country. Any change in the variables could see patients in need of respiratory assistance left without an alternative.

According to a summary of the project proposal that 256BN has seen, Uganda has just 12 functional Intensive Care Units equipped with a total of 55 functional beds implying an estimated 55 ventilators. That number translates into 1.3 beds and ventilators per million people. The ventilator project’s proponents further point out that the ventilators on the market are prohibitively expensive. They are available to low income countries such as Uganda at a concessional price of $25,000 per unit.

“There is therefore need for low cost ventilators that can be manufactured locally. Such ventilators would bolster the country’s surge capacity to provide critical care in case the demand for such care increases,” the project team says.

The ventilator being proposed by Kiira Motors Corporation and the School of Public Health at Makerere University, is based on open access designs from the Massachusetts Institute of Technology, the University of Florida, and other Public License Ventilator Technology Developers. KMC and the School of Public Health plan to adapt these designs to the African setting with an emphasis on localization of the supply chain to support just in time mass production.

“The capacity developed in the area for local content participation in the manufacture of Low-Cost Ventilators will be valuable to Uganda even post the COVID-19 Pandemic,” Kiira Motors and Makerere University say in their proposal.

They further argue that in light of the current spike in demand for the devices, surges in conventional ventilator production are unlikely to satisfy global demand and will come at higher prices. Analysts’ project that the United States will for instance, the COVID-19 pandemic will result into ventilator shortages in the region of 300,000-700,000 units.

The team reasons that it should be easy to produce the proposed ventilators domestically because their basic architecture, operating mechanism and underlying technology is similar to powertrain systems for vehicles, whose design and production, Kiira Motors has been engaged in for a decade now.

“That why it is not surprising to see several global automotive manufacturers such as General Motors, Mercedes Benz, Tesla, Ferrari among other, have been able to switch vehicle plants to manufacturing of Ventilators in some cases using parts of their vehicle model supply chain,” Kiira Motors and Makerere University argue.

They add that the collaborative effort draws on the institutional memory that Ugandan health professionals have developed from management of other epidemics such as Ebola, which resulted in the resultant development of the patented Epi Tent.

“The capacity Kiira Motors Corporation has developed in Electric Vehicle Systems Development position this collaborative effort as a timely intervention leveraging national resource available at established facilities at Luweero Industries Limited, Uganda Industrial Research Institute, among others, to engender the manufacturing of key components and support the short to medium term production needs,” the paper concludes.

African Heads of state head to South Korea next week for Summit talks

African Heads of state head to South Korea next week for Summit talks

Trading leads as main source of income for Ugandans

Trading leads as main source of income for Ugandans

New leadership for bankers’ umbrella as total assets top $12 billion

New leadership for bankers’ umbrella as total assets top $12 billion

Brussels Airlines to announce Nairobi service

Brussels Airlines to announce Nairobi service

SITA promises enhanced travel experience after Materna acquisition

SITA promises enhanced travel experience after Materna acquisition

Saudia’s 105 aircraft order stretches A320neo lead over rival Max

Saudia’s 105 aircraft order stretches A320neo lead over rival Max